We employ a modern approach to fair and sustainable natural rubber farming. Our rubber is grown and produced to the highest quality, matching supply and demand with as little impact as possible.

our land stewardship

Our land in Cameroon and Malaysia spans 110,000 hectares, although the majority of this land does not produce natural rubber.

In fact, only 38,000 hectares is dedicated to high-quality rubber production land & internal community areas. Beyond this, we proudly steward 67,000 hectares of undeveloped and open natural forest – for scale, this represents a land mass over 6 times the size of Paris. This stewardship represents our commitment to preserving local biodiversity and maintaining a critical ecosystem. It also safeguards the forest’s natural resources for the benefit of indigenous communities who may inhabit these areas.

No deforestation

This is in line with our No Deforestation policy, verified annually through 3rd-party satellite imagery.

Low-intensity planting programme

This will see the growth of 13 million rubber trees by 2030, producing 100% traceable centrifuge latex, latex grades CV/L, and TSR 10/20.

A community partner

As Cameroon’s largest private employer, we strive to support the socio-economic development of the local communities.

Factories

Our Cameroon factories supply 100% traceable and sustainable natural rubber and latex from our plantations.

A tactical shift to prioritise the production of high-quality centrifuge latex saw an investment of twelve new centrifuges and an upgrade to the waste-water system in Hevecam. It also saw the construction of a state-of-the-art Sudcam factory, purpose built to supply the medical industry. Forecasted peak production: 50,000mT centrifuge latex & 30,000mT TSR grades respectively.

The factories are accountable to 3rd party-certified LATEXPRO and HEVEAPRO processing standards with 1,000 point audits.

Environmental Protection

62% natural forest

Our commitment to no deforestation and protecting 62% of our land as natural forest is verified annually by 3rd party satellite imagery.

Responsible operations

We maximise the efficiency and productivity of our resources whilst minimising waste and emissions. This includes investment in solar energy, effluent water recycling and the monitoring of air emissions.

Net-zero

Our roadmap to net-zero has commenced with an ambitious carbon mapping programme. This will lead into a decarbonisation strategy to follow the Science Based Targets initiative (SBTi) and Paris Agreement goals.

Our Communities

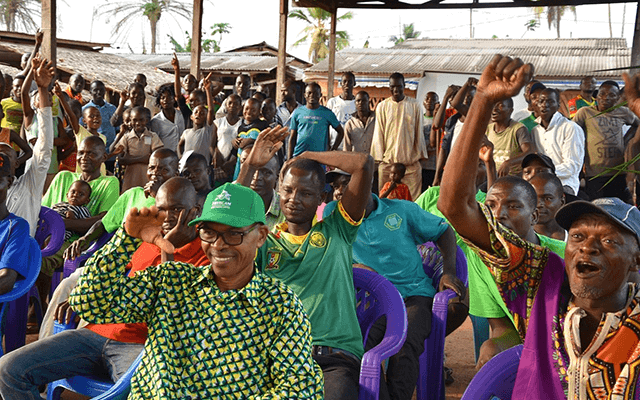

As a modern employer, we continuously identify new opportunities for education, empowerment and socio-economic development.

Daily necessities and community infrastructure is provided and maintained across our Cameroon plantations. This includes family housing for 40,000 individuals, 58 government-certified schools for 11,100 students, 2 hospitals, as well as sport and community facilities.

Community Engagement

Social Action Plan

This 5 year plan supported the socio-economic development of over 40 local and indigenous communities, in conjunction with local NGOs.