At Corrie MacColl, we recognize the critical role natural rubber plays in global industries and the impact its production could have on the environment, communities, and ecosystems. As a responsible leader in the natural rubber supply chain, we are committed to ensuring that our operations and sourcing practices promote the very highest levels of sustainability and ethical standards.

Responsible Sourcing

FSC ®

We connect our customers to FSC® certified product and provide support in building FSC® supply chains. In addition to our Chain of Custody Certificates, we are preparing for an application of FSC® Forest Management certification in Cameroon. FSC® C132544

Environmental Protection

62% natural forest

Beyond our 38,000 hectares of rubber plantation & internal community areas, we steward 67,000 hectares of undeveloped and open natural forest under a no-deforestation policy – for scale, this represents a land mass over 6 times the size of Paris. This stewardship represents our commitment to preserving local biodiversity and maintaining a critical ecosystem. It also safeguards the forest’s natural resources for the benefit of Baka and Bagyeli indigenous communities who may inhabit these areas.

Responsible operations

We maximise the efficiency and productivity of our resources whilst minimising waste and emissions. This includes investment in solar energy, effluent water recycling and the monitoring of air emissions.

Net-zero

Our roadmap to net-zero has commenced with an ambitious carbon mapping programme. This will lead into a decarbonisation strategy to follow the Science Based Targets initiative (SBTi) and Paris Agreement goals.

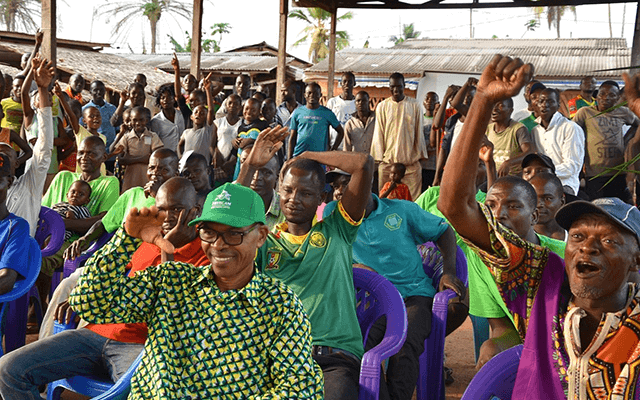

Our Communities

As a modern employer, we continuously identify new opportunities for education, empowerment and socio-economic development.

Daily necessities and community infrastructure is provided and maintained across our Cameroon plantations. This includes family housing for 40,000 individuals, 58 government-certified schools for 11,100 students, 2 hospitals, as well as sport and community facilities.

Community Engagement

Social Action Plan

This 5 year plan will support with the socio-economic development of over 40 local and indigenous communities, and is implemented by local NGOs.